Introduction

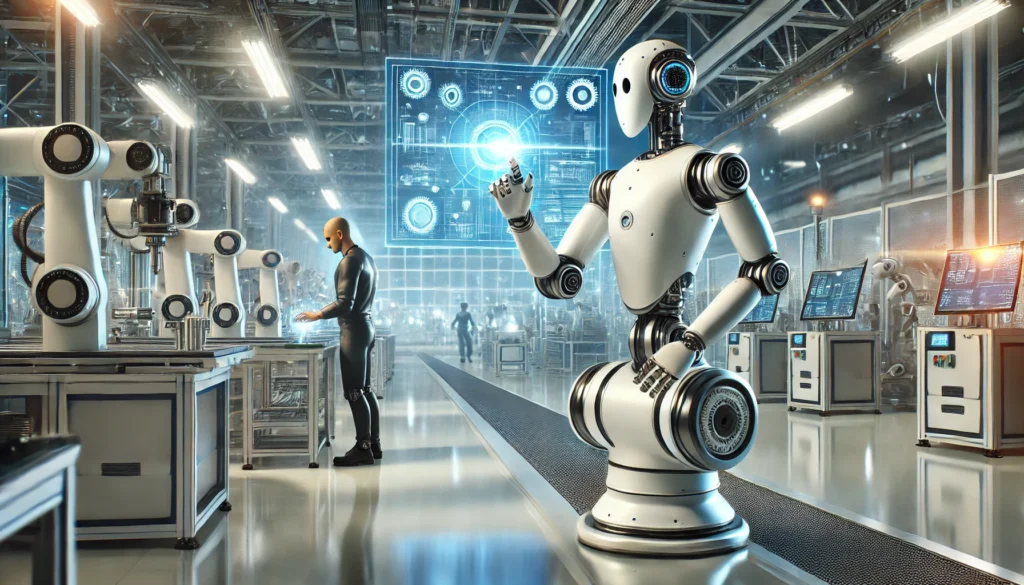

A new kind of robot has made its way into industrial settings, challenging our preconceived notions of

robotics. These robots’ main feature is the ability to work safely alongside humans, and now it seems human-robot

collaboration is the most sought-after characteristic for robots. There’s a lot of talk about them on the web, but

what are they really?

Until now, robots have always been big, strong, robust devices that work on specific tasks which were designed

for them. They’ve been kept in cages and surrounded by guards for safety purposes. Their bright color was used to

warn surrounding workers about the danger they represented. And it took a lot of programming skills just to set

up these robots.

Collaborative robots, on the other hand, are designed to work with humans. They’re built with safety features

such as integrated sensors, passive compliance, or overcurrent detection. The integrated sensors will feel

external forces and, if this force is too high, lead the robot to stop its movement. Passive compliance is produced by

mechanical components. If an external force acts on a joint, this joint will submit itself to this force. So, in the case

of a collision, the joint will move in the opposite direction or stop completely to avoid causing injury.

Most collaborative robots can be easily taught by demonstration, rather than requiring a deep knowledge of

programming. Thanks to their ease of implementation and the fact that no additional safety features are required

(no fences, switches, etc.), they can be brought on-line much more quickly. The majority of collaborative robots

can also be moved around the factory floor in order to perform a different task at another station. Being more

dexterous and flexible, they can perform more tasks and even do whatever a human can do.

In short, collaborative robots are the ideal new co-worker. In this article, you’ll discover all kinds of collaborative

robots that are either currently on the market or about to enter it.

WHAT DOES COLLABORATIVE ROBOTS MEANS?

Before we get into the details about collaborative robots, let’s get up to speed on the different terminology used

in the robotics world. It can get confusing (even for us) because people sometimes use certain terms interchangeably, such as “force limited robots,” “collaborative robots,” and “cobots.” They may have the same general purpose,

but they can be interpreted very differently.

In fact, all these terms mean the same thing: a robotic device that is made to work in collaboration with humans.

Or, more specifically, a robot that will help a human worker execute tasks that are too hard on his or her body, such

as lifting heavy weights or doing repetitive movements. The number of applications that can be done by robotic

co-workers is virtually unlimited

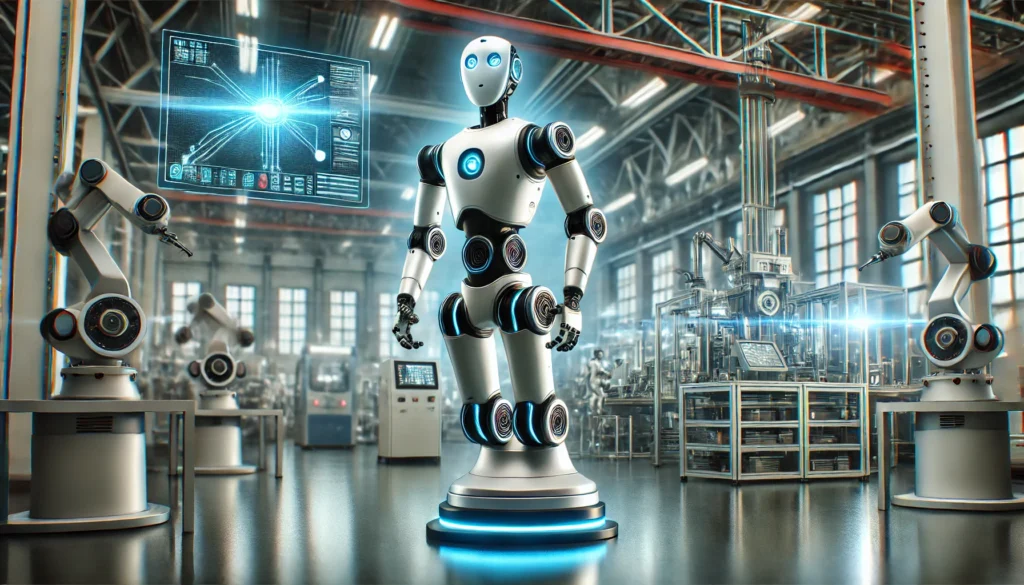

WHAT ARE COLLABORATIVE ROBOTS OR “COBOTS”?

According to ISO/TC 299, a collaborative robot or cobot is defined as a robot designed to interact directly with humans in a defined collaborative space . The idea of collaborative robots was introduced by Colgate, Edward, Peshkin, and Wannasuphoprasit (Colgate et al., 1996), who focused on the simplest possible version with only a single joint, also known as a steerable wheel. Since then, several versions of cobots with different technologies embedded in them have been introduced in the market . According to the International Federation of Robotics (IFR), the market for cobots is still growing, and the end-users and engineers are still exploring the best configuration in terms of sensors, grippers, and intuitive programming interfaces for

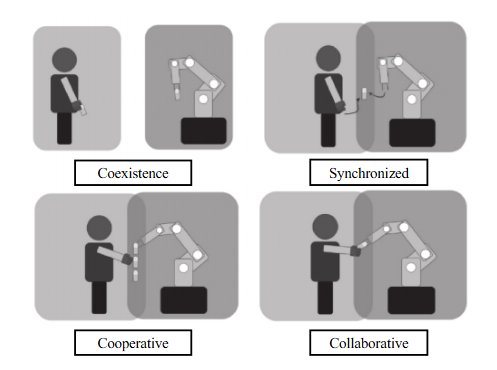

The primary purpose of cobots is to be used in a shared workspace along with a human worker without fences to perform tasks involving varying levels of inter- action. Different types of interactions are possible in a shared working environment, namely, coexistence, synchronization, cooperation, and collaboration

FORCE LIMITED ROBOTS

A force limited robot uses one of the 4 types of collaboration that can be accomplished with robots. In fact, a

force limited robot is a robot that’s specially designed to work alongside humans. They have built-in force torque

sensors that detect impact and abnormal forces. The sensors stop the robot when overloaded.

This means that if the robot’s arm hits something (…like a worker), it automatically stops to protect its human

colleagues. These features aren’t present on industrial robots, and they’re the reason why force limited robots can

work alongside humans without any fencing. Regular industrial robots must be isolated because they neither feel

nor monitor their environment

Force limited robots also tend to have rounder shapes than regular industrial robots. This means they cause less

harm when they collide with something else. A round shape spreads the force over a bigger surface area and

reduces the pressure applied to an external object (or person). Some force limited robots even have cushioned shells that absorb shocks and reduce the effect of deceleration on a human body part, which results in a less

harmful impact.

COBOTS

“Cobot” is a slang term used to describe a collaborative robot. Once again, the term “cobot” is mostly used when

talking about force limited robots. So you can basically say that a force limited robot is a cobot.

While an industrial robot can be used for collaborative tasks, it’s usually not force limited, and these types of robots

tend to need supplementary monitoring devices in order for them to safely execute tasks alongside humans. The

misnomer is so widespread that even we sometimes confuse them in our publications! (But not this one, of course.)

PAYLOAD

The payload is the weight that the robot can carry. All robots have a given payload, which is calculated without the weight of the end effector or robot tool. This means that the real payload that can be carried by the robot is the nominal payload minus the weight of the robot’s end effector. When going further in the robot analysis you might want to reduce the maximum payload that will be carried by the robot, depending on the acceleration and data

such as the friction coefficient.

ROBOT WEIGHT

The weight of the robot indicates whether you can relocate the robot easily, or if you will need a forklift to do so.

On some shop floors, the robot will be relocated near-constantly to perform different tasks. Keep in mind that if

the robot is too heavy, you will need an entire team to bolt/fix it at its new spot.

REPEATABILITY

Most of the time people will ask about the accuracy or precision of a robot. But in the collaborative robot world, this specification is quite useless. In fact, what you should most want to know is the repeatability. Since cobots are usually programmed by teaching/hand guiding, the robot’s ability to recreate the exact same motion is more valuable than the robot’s ability to go at X, Y, Z within half a mm. In any event, most robots’ spec sheets list their highest

repeatability, so if you test the robot you will probably obtain a lower (and hence better) repeatability than the one specified.

“SAFETY”

Even though safety is a really complex subject when it comes to collaborative robots, certain manufacturers will qualify their robots’ safety level. In fact, they normally get a third party to issue a certification of safety. Since the agency with the most stringent approval process is the TUV (German Safety Association), many robots are approved by this third party. But since there are a lot of different variables in the “safety” accreditation of a robot, the only thing you need to know is this: just because your robot is certified safe, doesn’t mean your application is. You must always perform a complete risk assessment according to the ISO 10218 (or more recently the ISO/TS 15066).

EASE OF PROGRAMMING

This specification is tough to quantify. In our process of testing most of the robots in this eBook, we attempted to use them as if we were completely new to robots, and then assigned each one a usability score of 1 to 10. That being said, some interfaces and methods are easier for some people and harder for others, so this specification will always be somewhat subjective.

REACH

The robot’s reach is the measurement of the distance that can be reached by the robot’s wrist. This measurement is taken from the robot’s base. There are a lot of different measurements that can be considered in terms of “reach,” but we chose to use the greatest distance the robot can reach as our reference here.