What is an Electric Motor?

An electric motor is a device that converts electrical energy into mechanical energy so it is an electromechanical device. Electric motors operate on the principle of magneto-electromechanical energy conversion in which a magnetic field interacts with conductors carrying current to generate force, this is described by Faraday’s Law of Induction and Lorentz Force. These motors forms a basic component for all running machinery and appliances, used in industries, transportations, home appliances and all automated devices.

History of Electric Motors

A Brief timeline of electric motors: the history of electric motors outlines gradual discoveries and advancements spanning centuries:

1820 Danish physicist Hans Christian Ørsted discovered that electric currents produce a magnetic field, establishing the basis of electromagnetics.

1821 – English scientist, Michael Faraday discovers principle of electromagnetism and then built the first simple electric motor (Faradays disc).

1834: The first model of an electric motor capable of driving a machine was built by American physicist Thomas Davenport.

In 1886, Frank J. Sprague developed the first viable DC motor that was widely adopted in industries.

While AC power systems began to be developed in the late 19th and early 20th centuries it was not until similar developments were made with electric motors (induction motors, for example) that separate sources of electricity became more efficient and useful.

Working Principle of Electric Motors

Electromagnetic Induction: An electric current is generated in the conductor if it (the conductor) moves through a magnetic field. That is, this was the first observation that led to many motors as practical implementations of a phenomenon discovered by Michael Faraday.

Lorentz Force: A current-carrying conductor in a magnetic field experiences a force that is always perpendicular to the direction of current and magnetic field, known as Lorentz Force. That generates a force that moves the conductor, resulting in mechanical motion.

In the electric motor, electrical current passes through windings (often copper) located inside of a magnetic field. It creates an electromagnetic interaction with a stator which result in movement of rotor linked to output shaft of the motor.

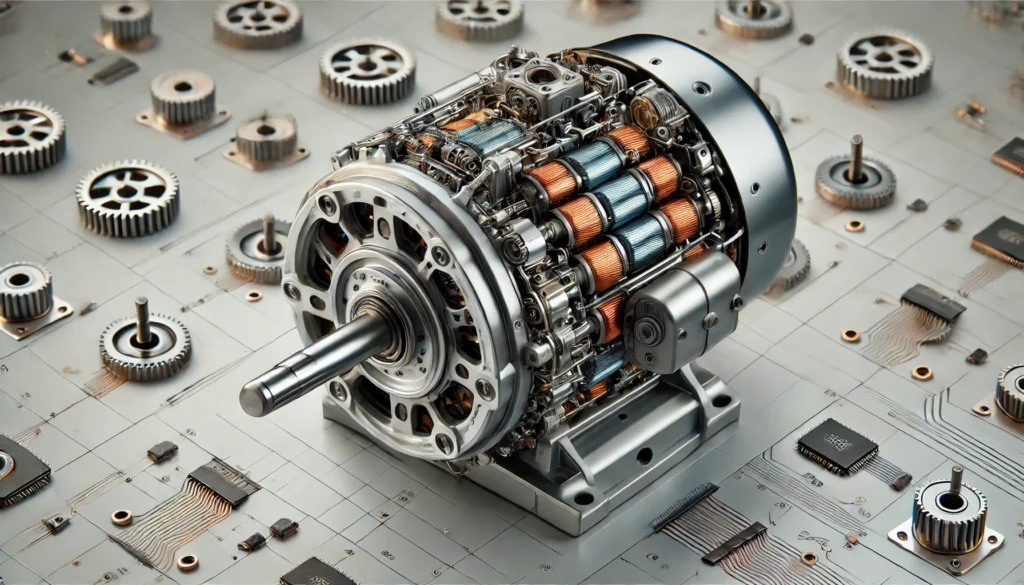

Main Components of an Electric Motor

Stator : Fixed part of the motor which generates magnetic field. It consists of either permanent magnets or electromagnets. The stator is responsible for creating the magnetic field used to operate the motor.

Rotor: The rotating part of an engine. This one is positioned inside the stator and can feel the force that is a result of interaction between such current and magnetic field. It is usually mounted on the output shaft, where the mechanical power is produced.

Commutator: The device that flips the current through the rotor so that it only rotates in one direction.

Brushes: In some motors (DC motor, for example), brushes ensure that electrical contact is made to the rotor through the commutator allowing current transfer

Bearings: Bearings provide smooth rotation of the rotor while also reducing friction between the rotor and motor housing.

Winding (Armature): The wire that is coiled in the motor and through which current flows. The electromagnetic interaction of the current in the winding and the magnetic field creates a torque.

Shaft: The shaft is the output element connected to rotor. It transmits the mechanical energy generated by the engine to an external load, which is often a pump, fan, or conveyor.

Types of Electric Motors

DC Motors Direct current (DC) is used in the DC motor for mechanical movement. You may find them in precise speed and torque-controllable applications such as robotics, electric vehicles, industrial automation.

Shunt DC Motor: The field winding is connected parallel to the armature giving a nearly constant speed for changes in load.

DC Motor in Series: the field winding is connected in series with the armature leading to a very high torque at start. This type of motor is suited for applications where a high initial torque comes to use – example: electric trains.

Compound DC Motor : Combines characteristics of shunt and series motors, with moderate speed regulation and high starting torque.

AC Motors:

Brushless DC Motor (BLDC) : They run without the brushes and commutators by changing the current in stator windings electronically. Compared to traditional brushed motors, BLDC motors are more efficient, reliable and durable.

AC motors work on alternating current (AC) and they are, no doubt an integral part of industrial world because of the strength of construction, ease of use and cost effective efficiency. They are classified into two basic types:

Synchronous Motors: The rotor in this type of motor will turn at the same speed as the magnetic field that is being generated by the stator. Where constant speed is needed such as in clocks, conveyors, electric pumps they used synchronous motors.

Induction (Asynchronous) Motors: The most widely used type of electric motor; induction motors operate based on the principle of electromagnetic induction. The Rotor itself is not powered, but him creating current based on the relative motion between rotating magnetic field generated and rotor themselves, to create the torque. Typical use of these motors is in the Fans, Blowers, Compressors, Gears and Industrial machines.

Single-Phase Induction Motor: A type of motor that is mostly used in residential usages like washing machine, freezer, etc., and operates from a single-phase supply.

Type of three-phase induction Motor: This Motor are used in Industries mainly as it is very efficient, It runs on three-phase power supply. Usage: Heavy-duty equipment, conveyors and big compressors.

Uses of Electric Motors:

Electric Motors used in thousands of industries and applications:

Electric cars: Electric motors for electric vehicles (EVs), trains, and even some aircraft They can also be found in elevators and escalators.

Household Appliances: Used in daily household appliances such as washing machines, vacuum cleaners, fans, air conditioners and refrigerators.

Industrial Automation: Electric motors operate machinery, conveyors pumps compressors and drive entire robotic systems on manufacturing and processing plants of all kinds.

Medical: Image devices, surgery instruments and prosthetic limbs rely on precision electric motors.

Renewable energy: Motors in wind turbines and hydropower plants convert kinetic energy into electricity.

Limitations of Electric Motors

High Initial Cost: Certain electric motors, such as synchronous and brushless motors (high quality), have the highest fabrication and to some extent installation costs.

Power Supply Dependency: Electric motors depend on a continuous power supply (which they lack in remote parts of the world where the electrical grid isn’t fully developed)

Volume and Weight: Electric motors could be large and heavy, making them unsuitable for applications requiring high power such as mobile or lightweight equipment.

Recent Advances in Electric Motors

Technological breakthroughs over the recent years have aided in enhancing these electric motors with higher performance, better efficiency and multiple functions:

High-Efficiency Motors: High-efficiency motors, including Permanent Magnet Synchronous Motors (PMSMs), have improved performance and energy consumption for applications like electric vehicles and renewable energy systems.

Smart Electric Motors: sensors, IoT and AI-driven control systems are making electric motors smarter so they can function more accurately and adaptively in our smart factories and other automated systems.

Lightweight and Compact Designs: especially in the aerospace and automotive sectors, where there’s significant pressure on design engineers to minimize space requirements without compromising performance has been made possible by both advanced materials e.g., light-weighting engineered stator carriers/back-iron for higher torque-to-weight ratio, giving substantial mass savings at a relatively small additional cost.

Electric Vehicle (EV): One of the areas where electric motors have developed quite fast in recent years is EVs, as those are taking over traditional combustion engine cars with their efficiency and minimal emissions while also offering lower maintenance costs.

Conclusion

Electric motors have become an essential feature of our modern lives, providing power to everything from industrial equipment to everyday consumer products. The great versatility, efficient operation, and electrical energy to mechanical motion conversion capabilities have reshaped industries and facilitated technological advances in many domains. As motor technology advances further with innovations in energy efficiency, smart controls, and eco-friendly materials, electric motors will remain vital in the future of energy system integration as well as mobility and automation.